Headlines

Spotlight on our new 4S milling machine

Speed and simplicity await you

Officially presented at the Leipzig exhibition in May 2012, the 4S milling machine completes our range of milling machines for orthopaedic devices.

Fitted with a 4th axis, this milling machine can mill flexible foam of different densities to directly produce seat braces, mattresses, soles thanks to a large table which can accommodate blocks sizes of Length 600mm x Width 600mm x Height 300mm.

Based on our S model structure, the 4S has the same rotary milling technical characteristics for braces, prosthesis, orthosis, helmets, AFO.

With the 4S, our objective is three-fold:

- Reduce the machining preparation time (CAM)

- Considerably reduce the machining time compared with other milling machines on the market

- Allow the machining mode to be changed quickly (rotary and flat)

Thanks to our new R4DMill software, all machining strategies can be programmed in less than a minute with powerful options such as constant scallop machining or progressive trimming.

Machining times have been reduced by 50%, meaning that a seat or a backrest for a seat brace can be machined in 22 minutes. It only takes 30 seconds to change from rotary milling to flat milling.

Its capabilities and price make this milling machining for orthopaedic devices the most versatile and affordable on the market.

News

Renew your support and update contracts

Your Rodin4D annual updates, technical support and maintenance contracts will expire soon.

So, now is the right time to renew them!

The “Rodin4D Update and Support” package ensures you always have the latest updates and technical support for software and 3D scanners.

The “Rodin4D Milling Update and maintenance” packages are for milling updates and maintenance. You can choose from 3 different packages.

We will be in touch with you soon so that you can renew your subscription for the 2013/2014 period.

Customer Satisfaction Survey

In early January, Rodin4D conducted a customer satisfaction survey with its French-speaking customers.

Our customer’s success is our driving force and each one of your remarks is important to us since it allows us to improve the value of our products and services.

This survey also allowed us to learn more about our customers. As such, we have discovered that 85% of you have already recommended Rodin4D to a friend or a colleague, and that 100% of participants think that Rodin4D improves productivity.

Thank you to all our French speaking customers for their valuable contribution.

This survey will be conducted soon in Germany and in other European countries to find out more about your vision of Rodin4D.

French speaking users day 2013

Diary dates!

To mark its 10th anniversary, Rodin4D would like to invite you to attend our French-speaking user days, dedicated to our solution, which will be held at Bordeaux on the 26th and 27th September 2013.

These user days provide a space to dialogue and share information with other users. This event will be organised to take into account the wishes you expressed in the customer satisfaction survey and throughout the year.

We hope to meet many of you at this event !

Tip of the month

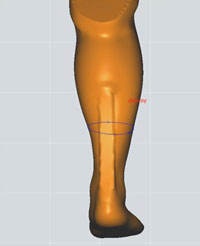

AFO: Draw the location of the carbon blade

Here is the result we wish to obtain:

To draw the location of the carbon blade for an ankle foot orthosis (AFO), here are the steps to follow:

- First add a flexion tool on 2 levels. The 2 levels limit the length of the blade.

- Make sure that the hollow area below the ankle is flat.

- Add a “cube” type insert.

- Define the dimensions of the blade. Then, position it so that it is parallel to the flat surface.

- Check the position in the rear view and centre the blade again, if necessary.

- Add a Merge tool.

- Select the options: “furthest from” and “add only”.

- Apply the global merge.

- De-activate the insert.

- De-activate or delete the temporary flexion.

- Smooth using the standard tools.

Renew your support and update contracts

Renew your support and update contracts Customer Satisfaction Survey

Customer Satisfaction Survey

French speaking users day 2013

French speaking users day 2013